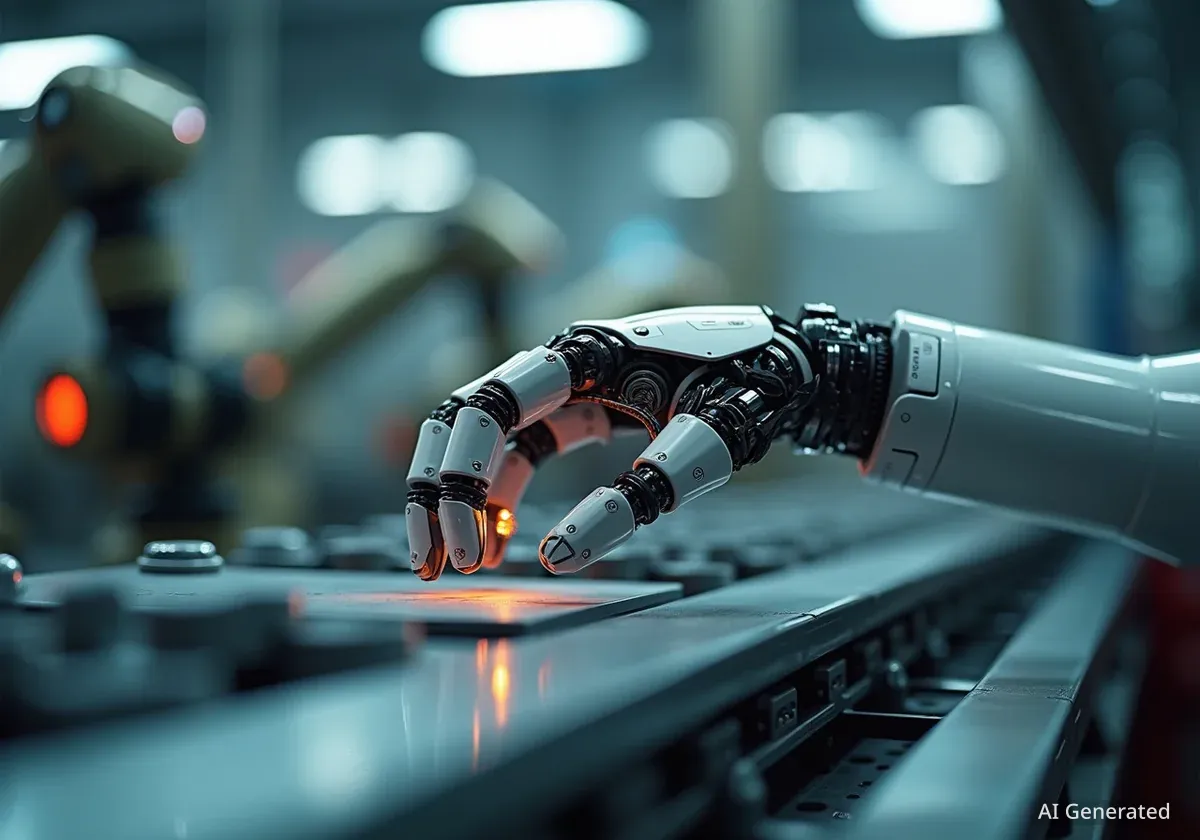

The next generation of humanoid robots, envisioned to transform global factories, faces a significant hurdle: developing hands capable of intricate tasks. This complex engineering problem, often referred to as 'the hands problem,' is delaying the widespread deployment of these advanced machines in industrial settings.

Key Takeaways

- Humanoid robots need advanced hands for factory work.

- Engineers struggle to replicate human dexterity.

- Solving this problem could unlock a $5 trillion market.

- Replacing muscle and skin with motors and sensors is complex.

The Quest for Human-Like Dexterity

Engineers and researchers across corporations and academic institutions have been working for years to create mechanical hands that can match the versatility of human hands. This challenge involves integrating complex motor systems, sensors, and robust materials into a compact, functional design.

The human hand is an incredibly sophisticated tool, capable of both powerful grips and delicate manipulations. Replicating this range of motion and sensory feedback in a robotic counterpart requires significant innovation in robotics and materials science.

"Creating the mechanical equivalent of the human hand is a challenge that has been stumping corporate and academic researchers for years," states a recent report.

Overcoming Design Obstacles

The primary difficulty lies in miniaturizing the necessary components while ensuring durability and precision. Traditional robotic grippers are often designed for specific tasks, lacking the adaptability needed for varied factory environments. Humanoid robots, however, are intended to be versatile, performing a wide array of functions currently handled by human workers.

Replacing biological muscle and skin with motors and sensors is a critical step. This involves not only mechanical design but also advanced programming to interpret sensory input and control fine motor movements. Achieving a natural, fluid motion remains a core focus for developers.

Fast Fact

Experts estimate that solving the 'hands problem' could unlock a global market for humanoid robots worth up to $5 trillion by 2050.

Potential Economic Impact

The successful development of highly dexterous robotic hands could revolutionize manufacturing and logistics. Factories could see increased automation, reducing the need for human intervention in repetitive or dangerous tasks. This shift could lead to significant efficiency gains and cost reductions across various industries.

The economic projections for this technology are substantial. According to market analysis, the global market for humanoid robots could reach trillions of dollars in the coming decades. This potential drives much of the ongoing research and development efforts.

Industry Context

Companies like Tesla have publicly highlighted the 'hands problem' as a key barrier to deploying humanoid robots like their Optimus model. This indicates the high priority placed on this specific technological hurdle within the robotics industry.

Beyond the Factory Floor

While factories are the immediate target, the implications of advanced robotic hands extend far beyond industrial settings. Such technology could eventually find applications in healthcare, domestic assistance, and even hazardous environments like disaster relief or space exploration.

The ability of robots to interact with complex objects and environments in a human-like way would open up entirely new possibilities for automation and human-robot collaboration. This versatility is what makes the 'hands problem' such a crucial area of research.

- Precision Assembly: Robots could handle small, delicate components.

- Tool Handling: Adapt to various tools without retooling.

- Logistics: Efficiently sort and package diverse items.

- Service Roles: Perform tasks requiring fine motor skills in human environments.

The Path Forward

Researchers are exploring different approaches, from biomimetic designs that mimic human anatomy to novel materials that offer greater flexibility and sensory feedback. The integration of artificial intelligence and machine learning is also crucial for enabling robots to learn and adapt their gripping strategies.

Progress in sensor technology, allowing robots to 'feel' pressure and texture, is also vital. This feedback loop is essential for preventing damage to objects and performing tasks with the necessary delicacy.

The journey to fully functional, human-like robotic hands is ongoing. However, the potential rewards—both economic and societal—are driving intensive investment and innovation in this challenging field.