Bedrock Robotics, a two-year-old startup founded by veterans from the autonomous vehicle company Waymo, has secured $270 million in a new funding round. The investment brings the company's valuation to $1.75 billion and will fuel its mission to automate heavy construction equipment like excavators.

The San Francisco-based company is developing artificial intelligence systems designed to address a critical labor shortage in the construction industry, aiming to augment human capabilities rather than replace them entirely.

Key Takeaways

- Bedrock Robotics raised $270 million, pushing its valuation to $1.75 billion.

- The company was founded by former Waymo engineers to automate construction vehicles.

- The technology is designed to be retrofitted onto existing equipment from major manufacturers.

- It aims to solve the construction industry's labor shortage, which requires an estimated 349,000 new workers this year in the U.S.

From Self-Driving Cars to Automated Excavators

Bedrock Robotics is leveraging expertise gained from one of the most complex AI challenges—autonomous driving—and applying it to the construction sector. Several of the company's founders, including CEO Boris Sofman, were instrumental in developing technology at Waymo, the self-driving car project under Google's parent company, Alphabet.

This experience with advanced sensors like lidar and sophisticated software is now being adapted for multi-ton machinery. According to Sofman, the goal is to bring the efficiency of digital AI to the physical world. "We’ve seen how powerful these A.I. approaches are on the digital side," he said. "What’s fun here is that it’s very practical."

A Simpler, Yet Complex Challenge

While navigating a construction site is less complex than driving through a busy city, automating heavy machinery presents unique challenges. Bedrock's technology must account for unpredictable terrain and the intricate movements required for tasks like excavation and demolition. The company's plan involves expanding its AI platform to other types of construction equipment over time.

Augmenting, Not Replacing, the Workforce

A central part of Bedrock's strategy is to support the existing construction workforce. The company emphasizes that its products are intended to make human operators more efficient and safer, not to eliminate jobs. This approach directly addresses a severe and growing labor gap in the industry.

The Labor Shortage by the Numbers

Forecasts from the Associated Builders & Contractors trade group indicate the U.S. construction sector needs 349,000 new workers this year alone to meet demand. That number is projected to increase to 456,000 next year.

Trey Taparauskas, CEO of Champion Site Prep, a contractor based in Texas and one of Bedrock's pilot users, confirmed the industry's challenges. "We’re always stretched thin," he explained, noting that labor pool restrictions have worsened the situation.

Champion Site Prep is currently testing Bedrock's technology on its excavators, with human operators supervising the machines as the AI learns. Taparauskas expressed surprise at the speed of development.

"They developed their technology so fast that it blew our minds. We’re three to five years ahead of where I would have expected to be when we first met these guys."

Major Investors Back a Vision of 24/7 Construction

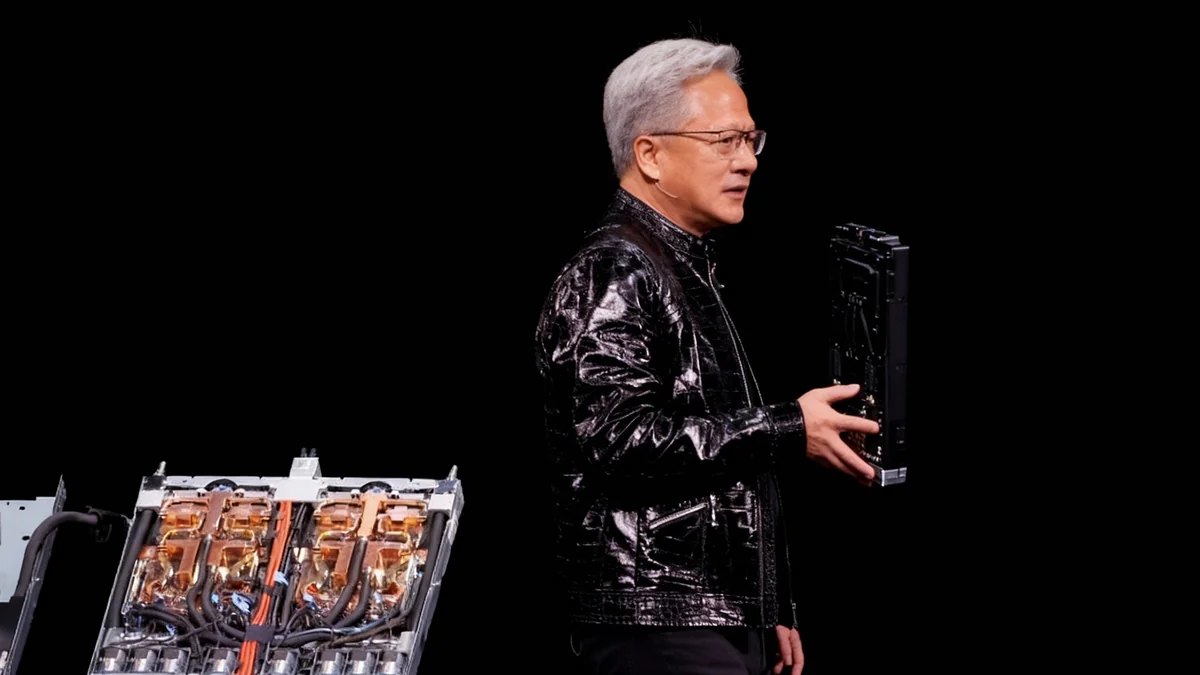

The $270 million funding round was led by CapitalG, an investment arm of Alphabet, and the Valor Atreides A.I. Fund. Other significant investors include existing backer 8VC and the venture division of Nvidia, a key player in the AI hardware space.

The investment reflects confidence in Bedrock's potential to transform a fundamental industry. Derek Zanutto, a general partner at CapitalG, said the firm was persuaded by the scale of the market opportunity and the technology's potential to fundamentally improve construction processes.

"It’s filling a void, fundamentally upleveling what humans on construction sites are doing," Zanutto stated. "You can’t build for the 21st century with a 1950s shovel and labor model."

The Future of Building

Bedrock's long-term vision extends beyond simply making worksites more efficient. CEO Boris Sofman envisions a future where automated machinery can operate around the clock, potentially 24 hours a day. This could dramatically accelerate the construction of critical infrastructure, including factories, housing, and the data centers needed to power the digital economy.

By designing its systems to be retrofitted onto equipment from established manufacturers like Caterpillar, Bedrock aims for rapid and widespread adoption. This strategy allows contractors to upgrade their existing fleets without purchasing entirely new, specialized machines, lowering the barrier to entry for adopting this advanced automation.