China is rapidly advancing its position in the global robotics industry, installing nearly 300,000 factory robots last year. This figure represents more installations than the rest of the world combined and signals a significant shift in manufacturing and automation capabilities.

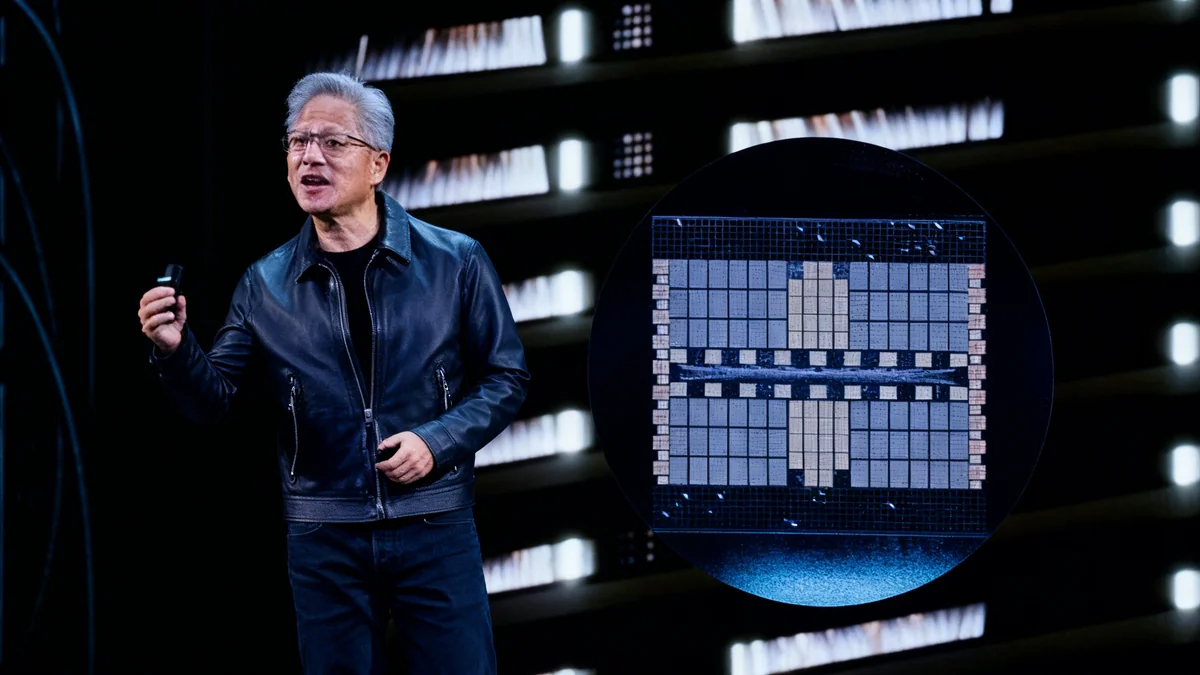

While the United States still holds advantages in areas like advanced AI chips and foundational research, China has established a dominant lead in robot hardware, large-scale deployment, and supportive government policy. This industrial strategy is positioning the country to lead the next wave of AI-powered physical technology.

Key Takeaways

- China installed almost 300,000 industrial robots in 2023, exceeding the combined total of all other nations.

- Over half of the robots installed in China were manufactured domestically, indicating a growing self-sufficiency.

- The U.S. installed 34,000 robots in the same period, with most being imported from Japan and Europe.

- China's strategy focuses on hardware manufacturing, rapid deployment, and a comprehensive domestic supply chain.

A Widening Gap in Robot Deployment

Recent data highlights a stark contrast in the adoption of industrial automation between the world's two largest economies. The numbers demonstrate a clear divergence in industrial strategy and manufacturing priorities.

According to a September report from the International Federation of Robotics, China's installation of nearly 300,000 new robots in its factories in a single year showcases an aggressive push towards automation. This is not just about quantity; it also reflects a maturing domestic industry.

By the Numbers

China's robot installations in one year were more than eight times higher than those in the United States. While China added almost 300,000 units, the U.S. added just 34,000, underscoring different rates of investment in automated manufacturing.

A critical detail is that over 50% of these robots were produced by Chinese companies. This trend reduces reliance on foreign technology and builds a self-sustaining ecosystem for robotics development and production.

The Foundation of China's Robotics Ecosystem

China's rapid progress is not accidental. It is built upon years of focused investment in creating a complete and efficient supply chain for robotics hardware. This industrial foundation allows companies to develop and scale products quickly.

Integrated Supply Chains and Rapid Prototyping

From essential components like actuators and sensors to the batteries that power them, China has cultivated a domestic supply chain that supports the entire lifecycle of robot creation. This allows startups to move from prototype to a viable, mass-produced product at an accelerated pace.

Many robotics companies situate their research labs near their manufacturing facilities. This proximity creates a fast feedback loop, where design adjustments can be tested and implemented almost immediately on the factory floor. This iterative process is a key advantage in a fast-moving technology sector.

The Role of Vertical Integration

Vertical integration is a common strategy among Chinese tech firms. In robotics, this means companies are producing key components in-house and sourcing raw materials from domestic suppliers. This approach gives them greater control over quality, cost, and production timelines, reducing vulnerability to global supply chain disruptions.

This efficiency has a direct impact on cost. For example, robotics company Unitree released its R1 humanoid robot in July for under $6,000. This price point was approximately one-third of its G1 model from the previous year, demonstrating rapid cost reduction and increased accessibility of advanced robotics.

National Strategy and Economic Drivers

The push for robotics is a core component of China's national economic strategy. The government is actively promoting the industry to address long-term demographic and economic challenges while fostering public interest in the technology.

Addressing Labor Shortages

With an aging population and a shrinking workforce, China views automation as a critical solution to maintain its manufacturing output and economic growth. Robots are being deployed on factory floors to fill labor gaps and improve productivity. This large-scale deployment also generates vast amounts of data, which is essential for training more advanced AI models that control the robots.

Policymakers have used high-profile events to build public support and showcase the country's technological achievements. The World Artificial Intelligence Conference in Shanghai and the inaugural World Humanoid Robot Games in Beijing featured robots performing complex tasks like boxing, dancing, and playing soccer, capturing public imagination.

As China analyst Dan Wang noted in his book "Breakneck," technological innovation in the country often "emerges from the factory floor, when a new product is scaled up into mass production."

A New Generation of Entrepreneurs

The leaders of China's emerging robotics and AI companies represent a new wave of technological entrepreneurship. Unlike the previous generation of tech pioneers who often looked to Silicon Valley for inspiration, today's founders are creating a distinct path.

Founders such as DeepSeek’s Liang Wenfeng and Unitree’s Wang Xingxing are seen as domestic role models. Both were educated exclusively at Chinese universities and are known for hiring predominantly local talent. This reflects a growing confidence in the country's own educational and engineering capabilities.

These entrepreneurs are operating in hyper-competitive domestic markets. The intense competition, sometimes referred to as neijuan or "involution," results in very thin profit margins. This pressure is a key factor driving many Chinese robotics companies to look toward global expansion, including markets in the United States and Europe.

They are building on the success of other Chinese technology giants like BYD (electric vehicles), CATL (batteries), DJI (consumer drones), and Huawei (5G networks), which have already established themselves as global leaders in their respective fields.

Global Implications and the Path Forward

The rapid rise of China's robotics sector has significant implications for the global technology landscape and industrial competitiveness. A December analysis from Citi GPS projected a future where robots manufacture more robots, potentially creating an enduring production advantage for nations that lead in this field.

For the United States to remain competitive, experts suggest a multi-faceted approach. This includes investing in critical infrastructure like the electrical grid to power future industries and forming joint ventures with allied nations to onshore manufacturing expertise for key robotics components.

Furthermore, continued investment in university-led fundamental research and policies that attract top global talent are seen as essential. A streamlined regulatory environment that supports entrepreneurship without excessive hurdles is also considered vital to fostering innovation.

The global race in robotics is intensifying. While the outcome is not yet decided, China's current trajectory in hardware production, deployment speed, and policy support has established it as a dominant force in the industry.